EXTRACTOR CUTTER

The extractor cutter is used to extract non-fluid products.

Specifications

Available in various sizes and models with capacities from 50 to 150 m2.

DESCRIPTION

The extractor cutter is used to extract non-fluid products.

Construction

- Construction in carbon steel or AISI 304 / AISI 316 stainless steel

- Auger with special profiles, compliant with product

Operating principle

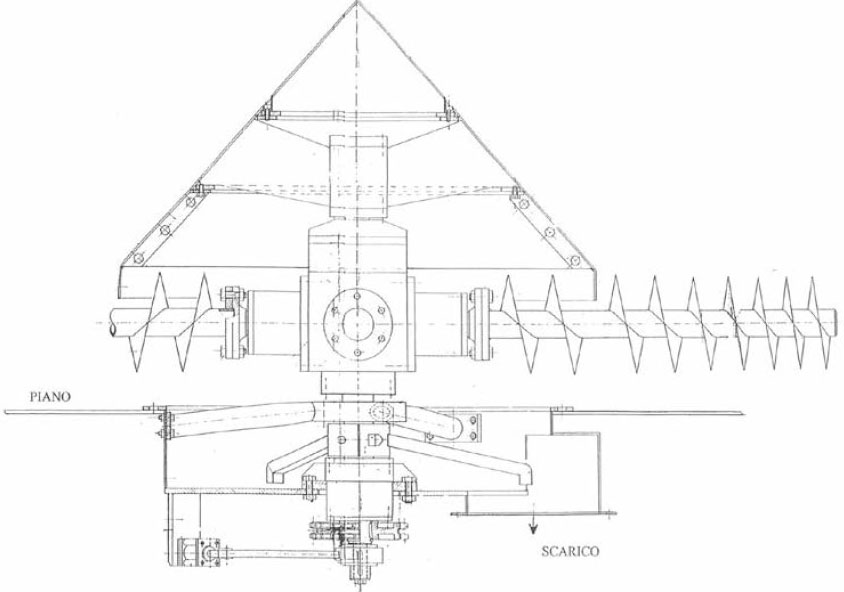

EF extractor cutters are mounted on the floor of the silo or hopper and allow the extraction of particularly difficult products that tend to pile up or stick together.

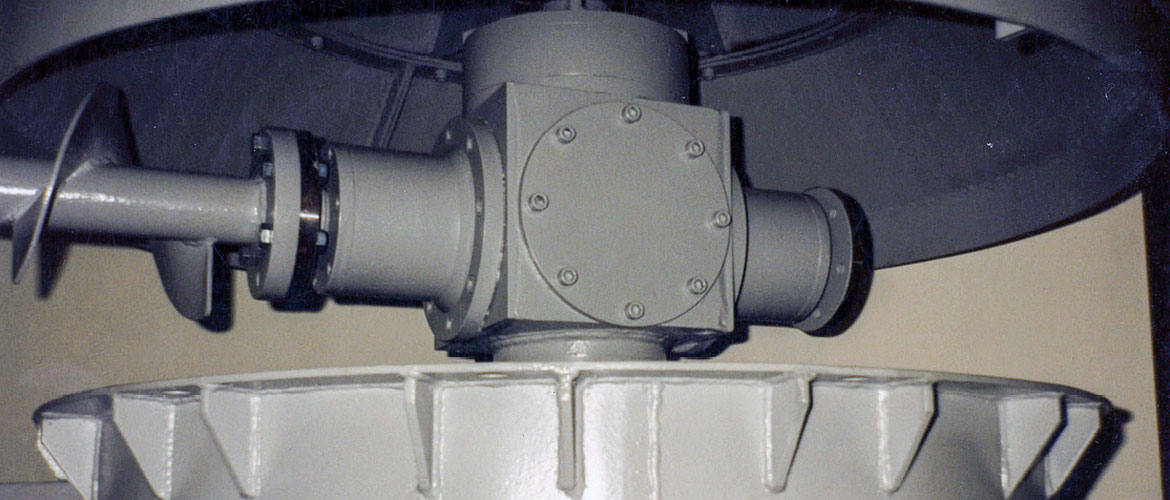

The extractor features two augers inside the silo that direct the product to a central box. From here, the product is discharged through a rotary reel; the central box is protected by a cone-shaped lid, normally supported by the head of the extractor in an idle state on its own shaft.

A special differential unit, driven only by the central control shaft, rotates the augers on their own axis; a pneumatically controlled ratchet gear transmits a rotary motion to the augers, such that they mill the product at any point on the silo floor.

During extraction, the product is efficiently remixed so as to mitigate any radial separation inside the silo.