PA-D Aspiration cleaner with decanter

Removes fine impurities and straw from the product.

It is inserted downstream of drying or collection only to clean dust or light impurities. It is indispensable for cleaning grain destined for warehousing, it "prevents overheating by husk and flours".

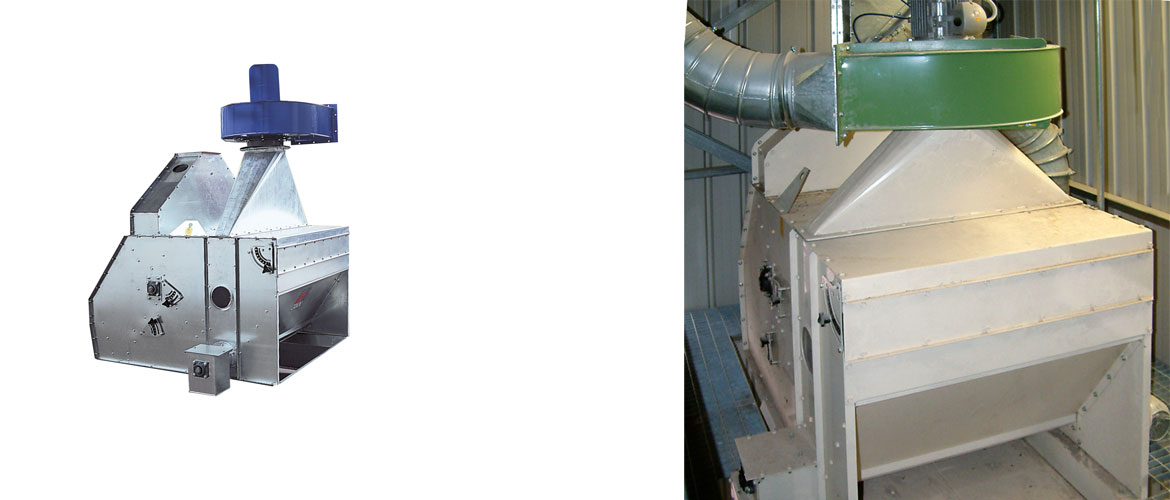

Air cleanersOperating principle

The product enters by way of gravity into a motorised roller distributor, and is evenly distributed across the entire width.

The product is curtain-dropped and struck by a cross-flow of air, which extracts the lightest impurities,

with the heavier impurities deposited in the decanting hopper, equipped with a waste expulsion auger.

The lightest impurities are decanted by a cyclone or filter.

Key

1. Uncleaned product inlet

2. Clean grain

3. Fine impurities

4. Dust outlet

Construction

- Aspiration casing in press-formed galvanized metal

- Product feed hopper

- Aspiration inlet with vertical or horizontal positioning

- Air flow regulation dampers

Optional

- Discharge hopper

Specifications

Available in various sizes and models with cleaning capacities from 30 to 180 t/h (calculated with wheat, specific weight 0.78 t/m3 - RH 14% Impurities 2%).