CR Rotary calibrator with/without aspiration

Separates grains into smaller fractions.

The capacity is obtained using the drum diameter and number of screens. Calibration precision is obtained using the rotation speed and drum inclination.

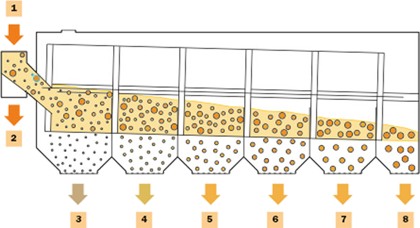

Operating principle

The product is fed by way of gravity into a cylindrical rotary drum covered with interchangeable perforated screens.

It then passes through various screening sectors with predetermined hole sizes.

The drum is then tilted in accordance with the roll-off angle of the product, which then falls into separate dedicated hoppers.

The choice of screen depends on the size of the product being calibrated.

Key

1. Calibrator product inlet

2. Product outlet (bypass)

3. Product outlet 1st calibration

4. Product outlet 2nd calibration

5. Product outlet 3rd calibration

6. Product outlet 4th calibration

7. Product outlet 5th calibration

8. Product outlet 6th calibration

Construction

- Drum casing and uprights in press-formed galvanized sheet metal

- Mobile side doors fitted with handle and lock

- Screens in perforated carbon steel

- Manual gradual drum inclination

- Wooden screen cleaning rollers

- Variable rotation speed

Optional

- Motorised drum inclination

- Internal product flow inspection window

- Variable speed with inverter

- Internal product flow monitoring camera

- Control panel

Specifications

Available in various sizes and models with calibration capacities from 1.5 to 45 t/h (calculated with barley, specific weight 0.6 t/m3 - RH 16% Impurities 2%).