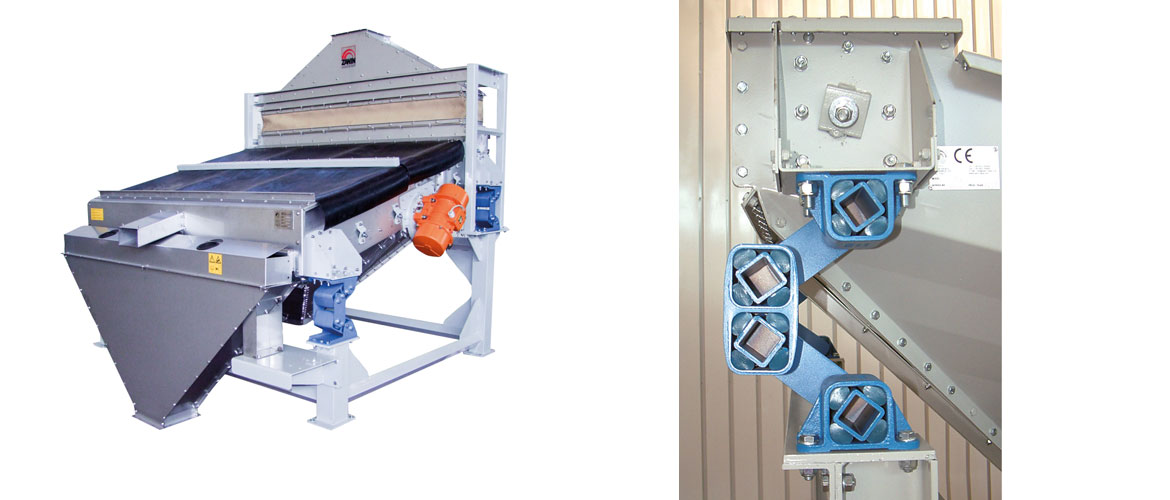

Vibro-sieve for chemical products

Separates large and fine impurities in the product.

Available in two versions: with one or two sieves

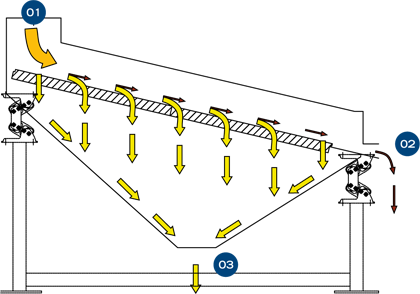

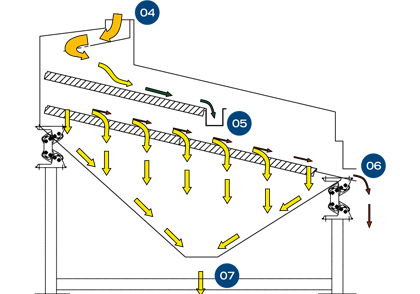

Industrial cleanersOperating principle

The product enters by way of gravity into a feed hopper and is evenly distributed across the entire width.

The product falls onto one or more sieves, separating impurities based on the type of perforation.

mod. VV-1

mod. VV-2

Key

1. Product inlet

2. First separation

3. Second separation

4. Product inlet

5. First separation

6. Second separation

7. Third separation

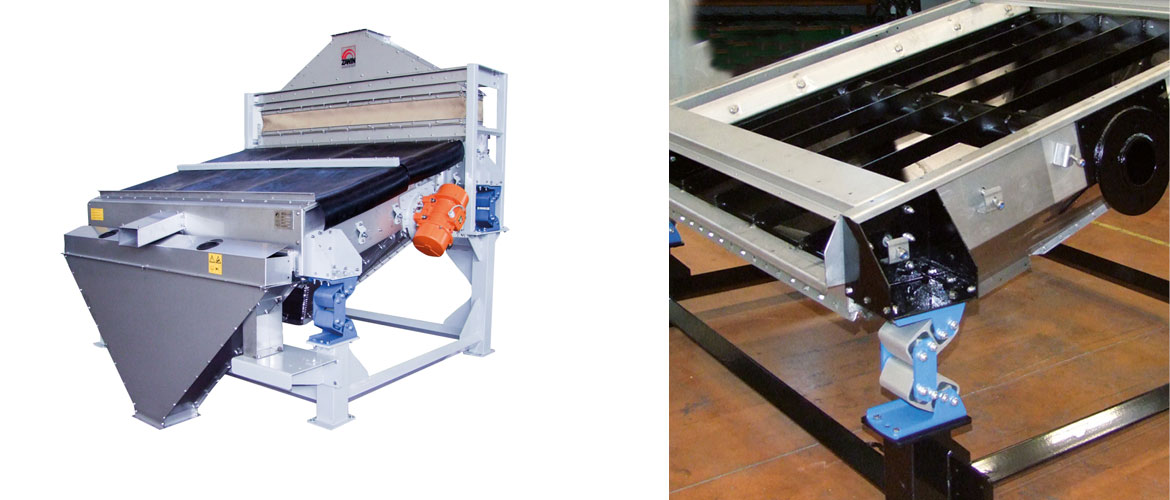

Construction

- Tank supporting frame made with galvanized metal profiles welded to each other.

- Tank in press-folded carbon steel, with bolted composing elements

- Product inlet spout support.

- Product feed hopper.

- Lamellar sieve supporting structure.

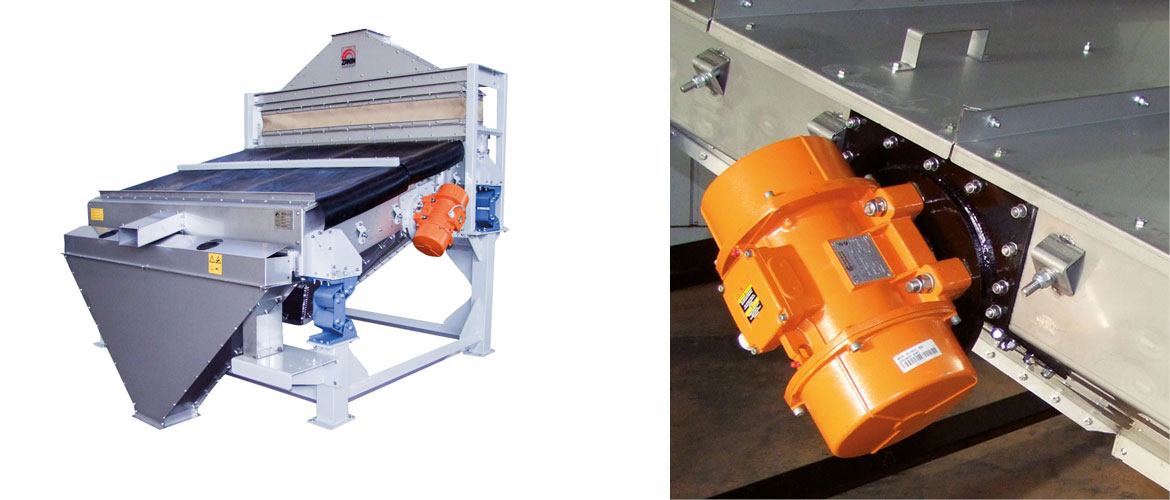

- Vibration transmission unit.

Optional

- Constructed in 304 stainless steel

- Wear-resistant sheet.

- Control panel.

- Discharge hopper.

- Clean product.

- Rejected product chute.

Specifications

Available in various sizes and models with capacities from 50 to 80 t/h (calculated with wheat, specific weight 0.9 t/m3 - RH 1% Impurities 2%).