Ventilation systems

Ventilation systems allow best preservation of ensilaged or warehoused grain.

By keeping the temperature and humidity of the mass moderately low and consistent, storage is possible for a limited period of time, without deterioration caused by various phenomena such as respiration, fermentation and the spread of parasites.

Specifications

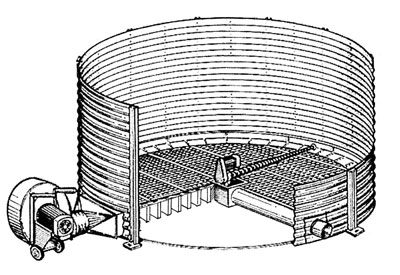

RAISED TOTAL VENTILATION

The ventilation system features a raised perforated floor, supported by a galvanized steel structure. The air flow generated by a fan or chiller enters underneath the floor and rises upwards, cooling the product.

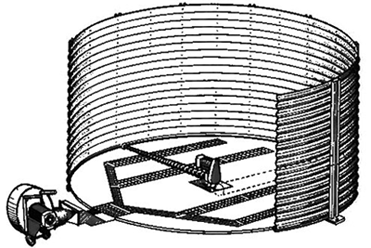

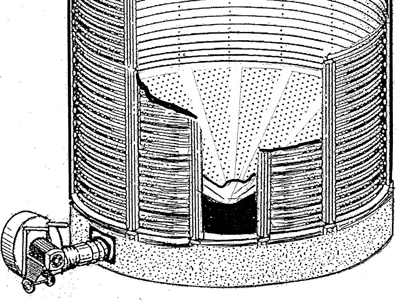

DUCTED VENTILATION

Ducted ventilation is widely used in newly constructed silos. The air flow generated by a fan or chiller enters the ducts and rises upwards, cooling the product. Storage residue can easily be cleaned off the ducts.

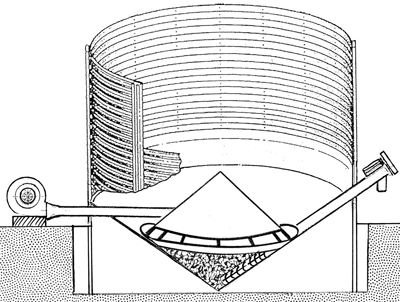

PERFORATED CONE AERATION

Perforated cone aeration is used in silos with a hopper. An economical system used to cool stored products.

INVERTED CONE AERATION

Inverted cone aeration is used in medium and low capacity silos. The air is inserted into the inverted cone and exits in the circumference. It rises upwards, cooling the product.

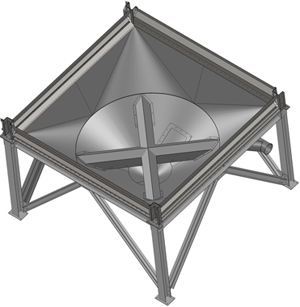

CROSS VENTILATION

Cross ventilation allows the insertion of air in four equal parts of the conical silo base. The air exits from the area below the cross and rises upwards, cooling the product.

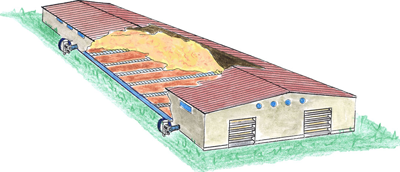

PERFORATED BLADE VENTILATION

Ventilation for the preservation of grain consists in the forced emission of air between the grains, enabling rapid heat exchange and thus reducing their temperature.

Two types of systems are installed on the floor of warehouses: aeration blades positioned on the same level as the ground, or vaulted ducting positioned on the floor of the warehouse.

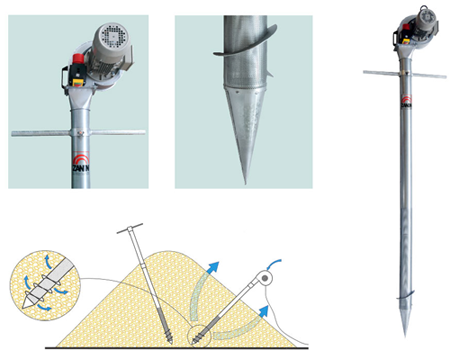

VENTILATION SPEAR - LVE

Used in storage systems due to its extreme ease of installation and removal.