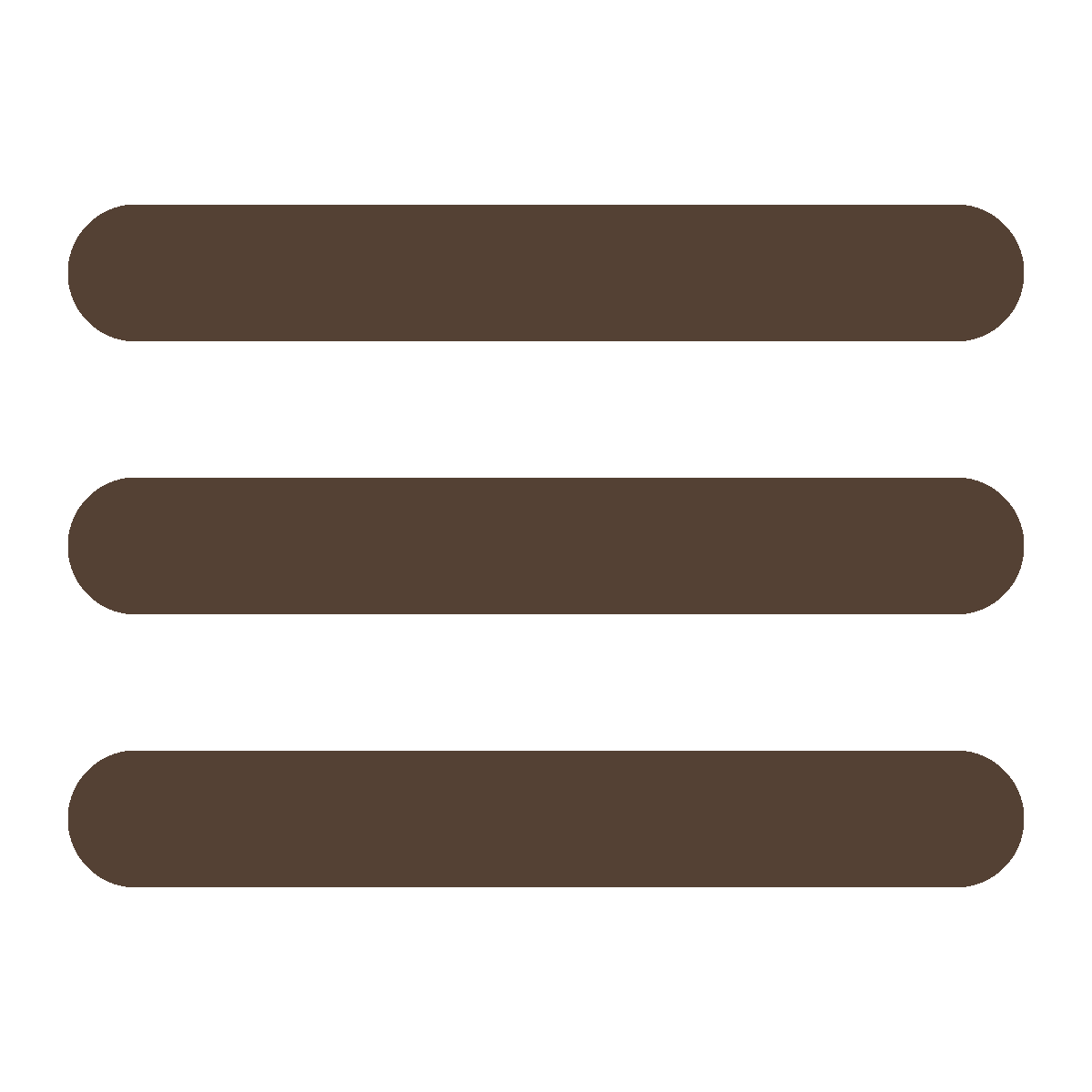

Destoner for cereals

Separates heavy impurities (stones, etc.) in grain.

The destoner with an internal fan is used to separate all impurities (such as stones, metals, lumps of earth, glass etc.) from various products like cereals, legums, nuts and dried fruits, which have a different floating speed and specific weight from that of the main product.

Seeds cleaning

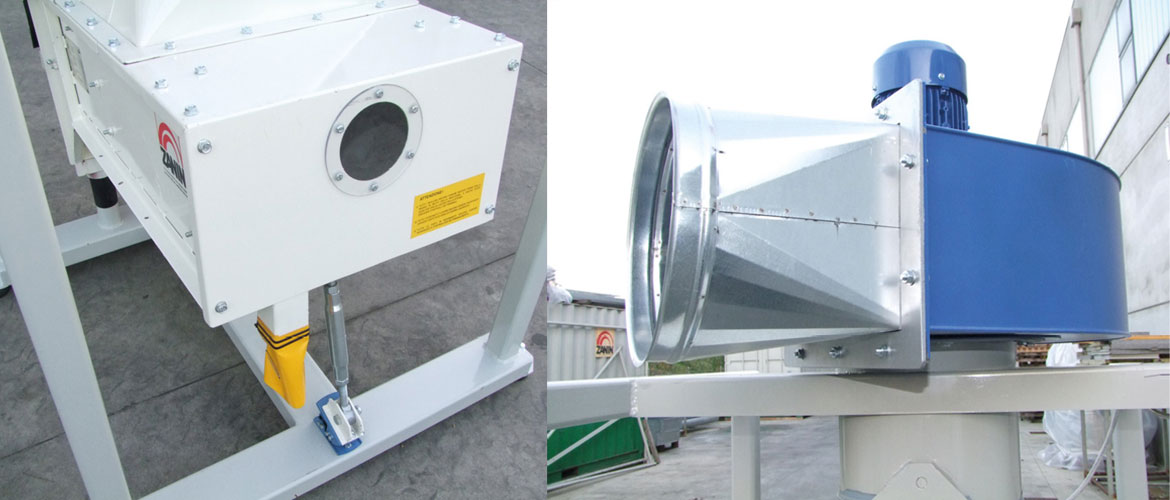

Operation

The product enters by gravity into a

dosing hopper and is evenly distributed

over the entire width of the destoner.

The product then descends onto a sieve

and the combination of vibration with an

airflow separates heavy bodies, which are

be channelled into a tarara, from the good

product.

Key

1. Product inlet

2. Air inlet

3. Discard outlet

4. Cleaned product outlet

5. Light impurity outlet

| MODEL | MOTOR Kw * | CAPACITY Kg/h* | DIMENSIONS (L x W x H) mm | WEIGHT kg |

|---|---|---|---|---|

| SDZ12 | 0.37 | 800/1.100 kg/h | 830 x 650 x 1430 | 90 |

| SDZ25 | 0.74 | 1000/2.500 kg/h | 1280 x 1060 x 1140 | 280 |

| SDZ50 | 1.47 | 4000/5000 kg/h | 1610 x 1300 x 1950 | 400 |

| SDZ80 | 5.52 | 6000/8000 kg/h | 2200 x 2100 x 2800 | 1400 |

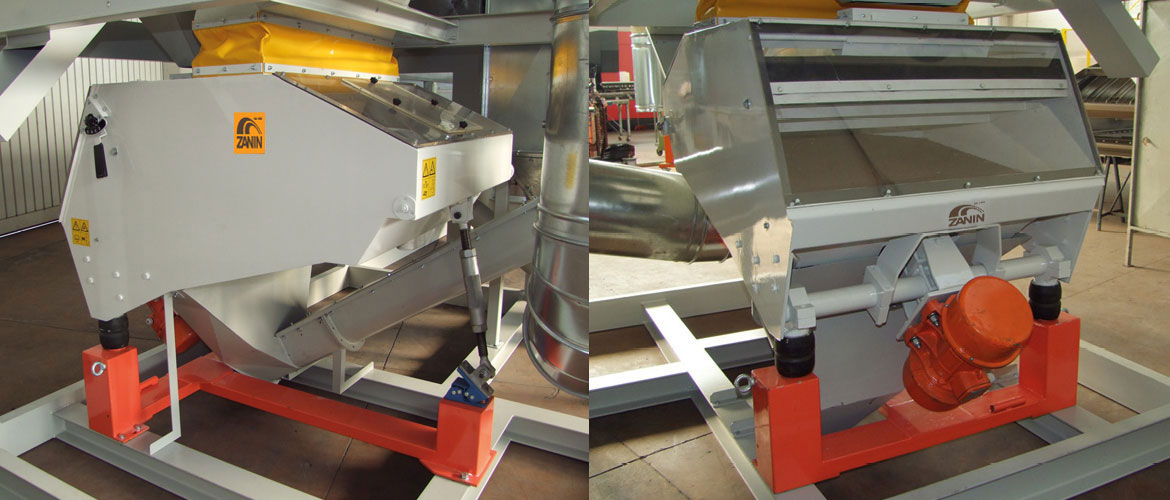

Construction

Frame supports casing in sheet metal with galvanised sheet profiles

- Folded sheet metal box, painted, with its various elements bolted together

- Product inspection porthole

- Inlet hopper produced with a manual adjustment damper for managing product flow

- Belt-drive motor

- Intake fan

Specifications

Available in various sizes and models with capacities from 800 to 8,000 kg/h.