SO Optical selector

Detects and removes products having the same colour, but with slightly different shades.

Optical selector with chutes and RGB three-colour cameras with the highest performance levels available in the market.

Features a full-colour RGB camera and led lighting system. The optical system can detect even the slightest difference in colour tone.

These characteristics reflect the current demands of food and non-food processing systems, which require optical selectors able to detect

and reject products having the same colour, but with slightly different shades.

Selector regulation is made simple thanks to the real image setting, allowing

remote connection and control via an internet connection.

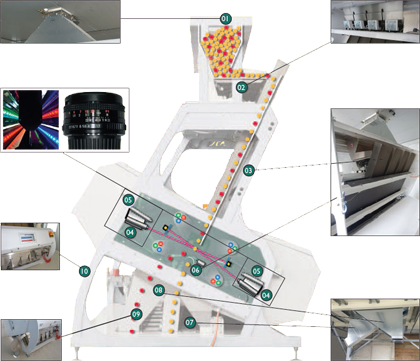

Operating principle

The product is inserted into the feed hopper, where it advances on a vibrating plate until sliding along a sloping chute.

At the end of the chute it free falls and is checked at 360° by a full-colour RGB camera (three-colour cameras in standard version) and by

additional NIR and InGaAs cameras (optional), positioned at the front and back of the chute.

Based on the signals sent by the optical system, the management software commands the pneumatic device, which physically separates the product that needs to be

discarded from that recognised as "compliant" and which by falling, naturally reaches the discharge hopper.

Discarded products are instead deviated by a blast of compressed air emitted by a solenoid valve, which corresponds with and is directed

towards the reject discharge hopper, located at the front of the selector.

In automatic two-step versions, the selected or discarded product is conveyed to another section of the same machine, where the exact same process is repeated.

Key

1. Product feed hopper

2. Vibrating plate

3. Sloping chute

4. Full-colour CCD RGB cameras

5. Additional NIR or InGaAs cameras (optional)

6. Solenoid valves

7. Compliant product discharge hopper

8. Reject product discharge hopper

9. Aspiration unit

10. Keypad

Construction

- Optical boxes, pressurised and air conditioned with a cooling system;

- Hermetic and sloping structure to prevent the accumulation of dust and product leaks;

- Receptacles to facilitate sampling of accepted and rejected products;

- Tilting optical boxes that completely open to facilitate cleaning and maintenance;

- Selectors equipped with standard flange for connection to dust extraction system;

- Additional connection available for extraction of dust directly into waste collectors (optional).

Specifications

Available in various models with configurable number of single-colour, two-colour, NIR and InGaAs cameras, according to various needs.