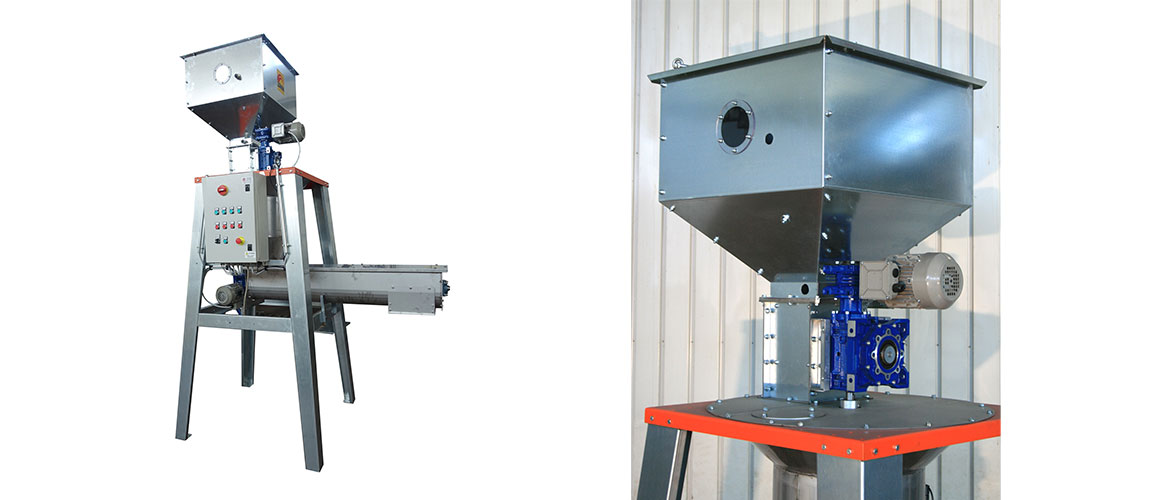

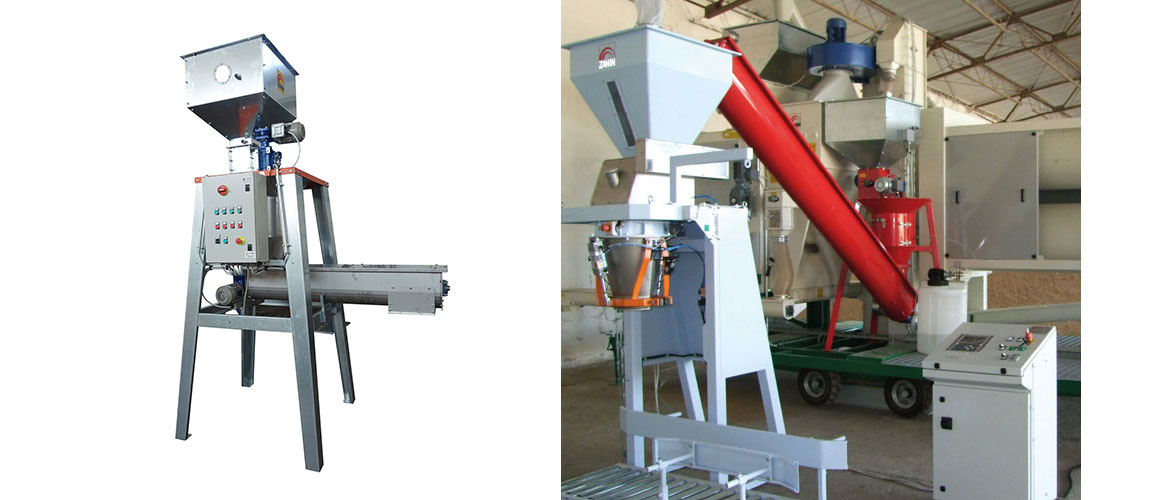

Operating principle

The product is fed by way of gravity into a hopper, then descends into a volumetric dosing unit driven by a rotary motion.

The product falls into the cylinder onto a swivel plate, where the liquid is injected, fed by a pump.

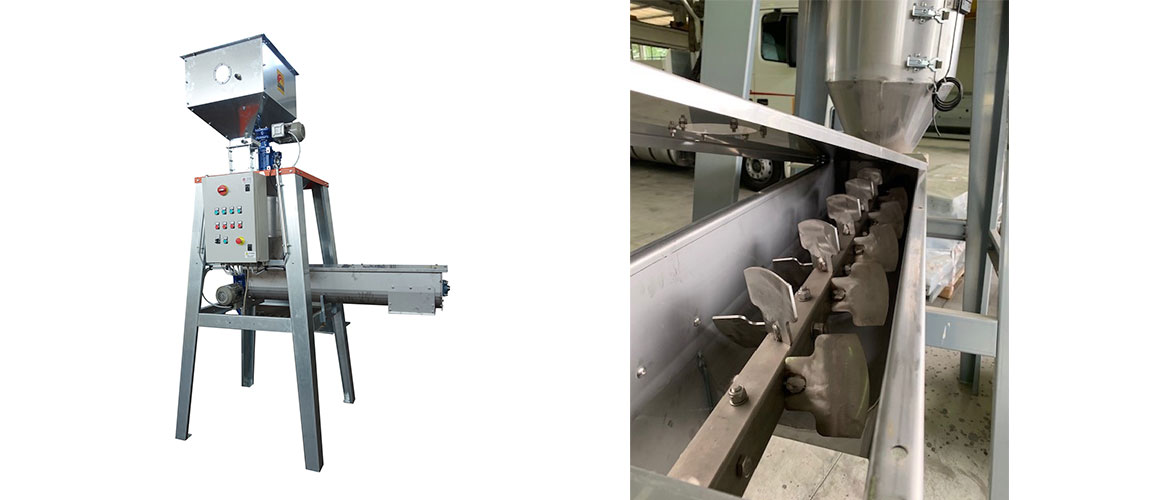

A blade auger, either horizontal or inclined, mixes the treated seeds.

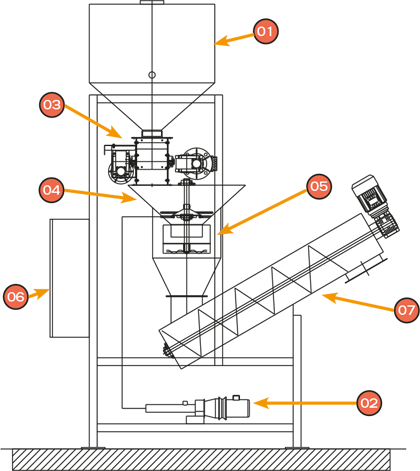

Key

1. Hopper

2. Pump

3. Volumetric dosing unit

4. Container

5. Swivel plate

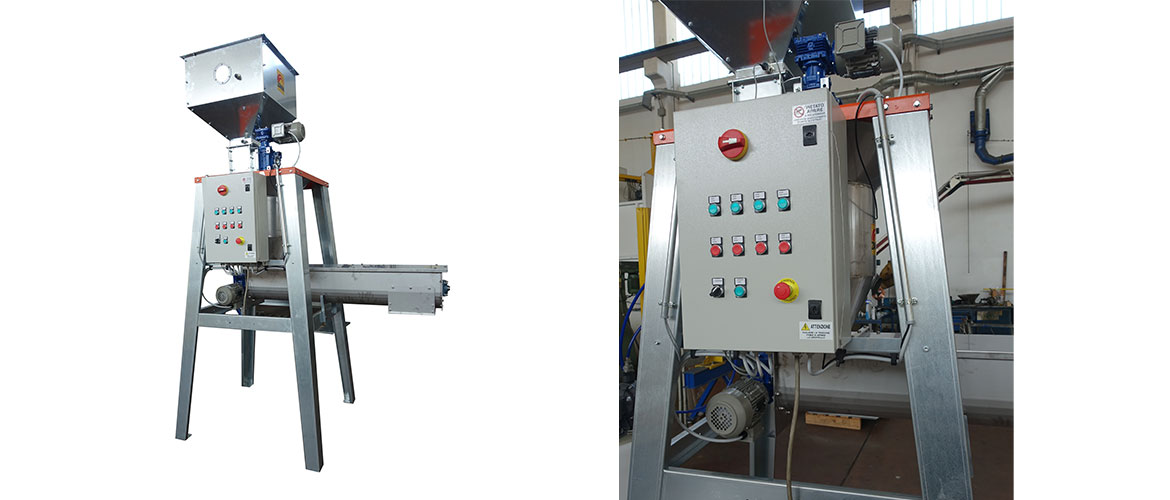

6. Electrical panel

7. Mixing auger

Construction

- Supporting frame in sheet metal with painted metal profiles, with bolted composing elements

- Auger in AISI 304 stainless steel

- Product feed hopper

- Direct drive motorisation

Optional

- Liquid additive transmission pump

- Pallet auger in stainless steel

- Inclined auger

Specifications

Available in various sizes and models for production batches between 1 to 12 t/h (calculated with specific product weight 0.78 t/m3).

Portable dosing unit for seed coating

The machine has been designed for the continuous wet treatment of seeds, including grain, corn, legumes and other.

The device consists in a product inlet, dosing pump and postmixer, coating chamber with distribution plate and liquid spraying nozzles

It is driven by gear motors. The coating device is controlled by a "Touch" control panel.

Operating principle

The dip tube is inserted into the container with the liquid, while the nozzles are safely inserted above an auger. When the dosing unit is enabled, the quantity of liquid inserted is mixed by the auger, which mixes the product with the liquid.

Key

A. Dip tube

B. Spray nozzle

C. Spray nozzle