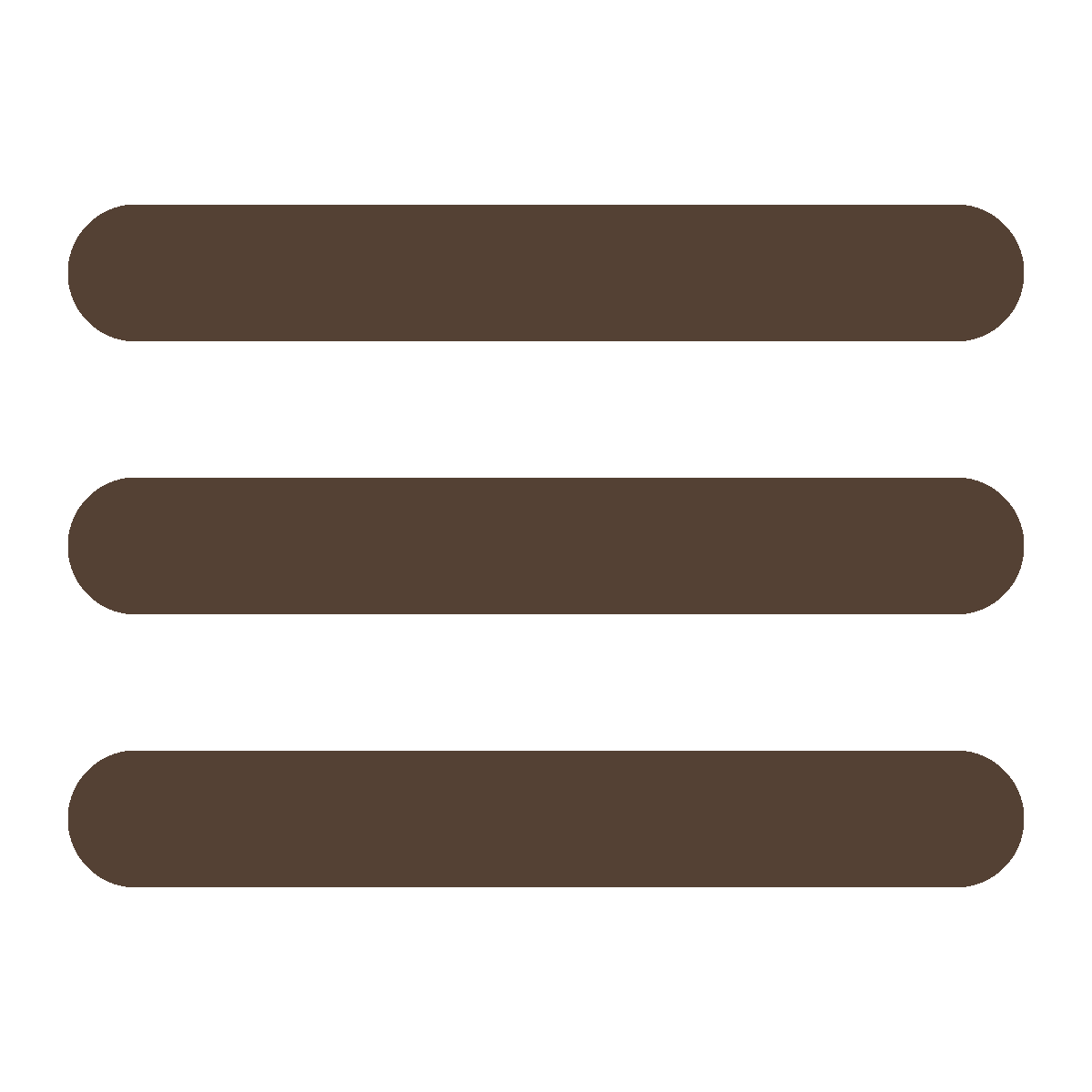

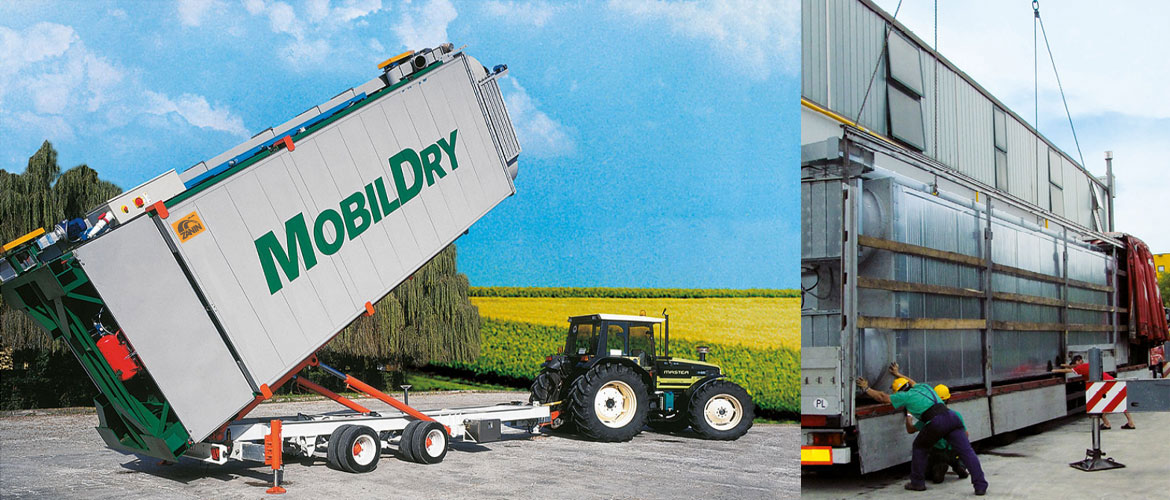

Mobile dryer, mod. MOBILDRY

Continuous/Recirculating

Advantages of mobildry

- Quality of dried product

- Generation of particulate matter within regulatory limits

- Standard sizes for transportation purposes

- Quick positioning

Specifications

Available in various sizes and models with capacities from 17.2 to 25.5 t.

COMPONENTS

Air ducts

The panels forming the air chambers are made of: mineral wool sandwich panels, heated air

section and saturated heated air section (prevents the formation of condensation and mulch inside the chamber).

Smooth interior and exterior walls.

Versions: Aluzinc-Galvanized-Precoated in various colours - Aluminium-Stainless steel 304.

Reinforcing uprights and ledges with rung ladders are installed inside the dryer for control and maintenance purposes.

Fans

The depressurised drying system, offering maximum attention to detail, is the most suitable for dust containment.

Each dryer is equipped with axial fans with variable or fixed pitch blades with different diameters, exploiting the machine's output and minimising consumption.

Zanin uses technologically advanced brands in the European fan sector to optimise the characteristics of its products.

Hot air generators

The following types of heating units are used for drying:

- direct fired

- indirect fired

- diathermic oil or steam

Possible fuels are:

- Methane gas

- LGP

- Diesel

- Heavy oil, vegetable oil or sub-products

- Biomass

The following types of burners are used:

- pressurised (diesel, heavy oil, gas)

- air (methane gas, LPG)

- special

Electrical cabinet

Dryers are equipped with electronic control devices and PLC management.

Electromechanical devices on request.

Elevators

The dryer has two loading/unloading bucket elevators equipped for connection to dust extraction systems.

Operating principle

Continuous

The drying column is formed by a bucket elevator that feeds the upper hopper, and a certain number of modules inside which ducts are buried in the grain. The grain drops by way of gravity in a zig-zag pattern.

The grain is struck by a counter-current of warm air in the top drying part, and room-temperature air in the lower cooling part. The exhaust air is dispersed directly into the atmosphere.

The quantity of grain in outfeed is predetermined and regulated by a pneumatic extractor. The product is subsequently collected in a discharge hopper and sent to a second bucket elevator, which lifts the product before sending it to its destination.

Recirculating

The drying column is formed by one loading/unloading bucket elevator only, which feeds the upper hopper, and a certain number of modules inside which ducts are buried in the grain. The grain drops by way of gravity in a zig-zag pattern.

The grain is struck by a counter-current of warm air along the entire column, and is dried through a continuous recirculating process until reaching the desired humidity level.

At this point, the burner stops and the product is cooled using room-temperature air only. The exhaust air is dispersed directly into the environment.

The quantity of grain in outfeed is predetermined and regulated by a pneumatic extractor. The product is then collected in a discharge hopper and sent back to the same bucket elevator, which lifts the product before sending it to its destination.