PSS Sieve cleaner and separator

Accurately separates impurities from the product.

Designed for the milling industry, where there is a strong demand for high hourly production rates and long-term reliability.

PSS operating principle

The product enters by way of gravity into a counterweight distributor, and is evenly distributed across the entire width.

The product is then curtain-dropped and struck by a cross-flow of air, which removes the lighter impurities through a winnowing process.

After the first separation, the product is conveyed into two processing compartments, equally divided for each sieving line.

Inside the two compartments, impurities and sub-products are separated according to the type of perforation.

When the clean product is discharged, it is evenly distributed across the entire width of the surfaces.

It is curtain-dropped again and struck by a cross-flow of air, which removes any dust and lighter impurities still present.

The latter are decanted through a winnowing process and the remaining fine dust is conveyed through a filtration system.

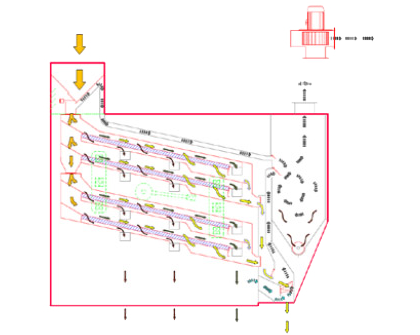

PSS 100

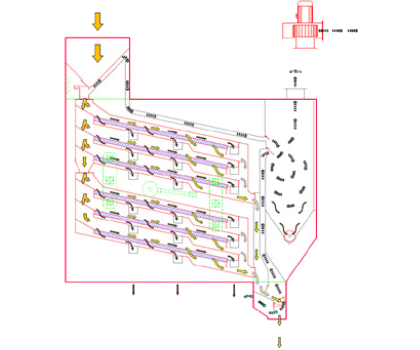

PSS 200

Key

Construction

- Box supporting frame in thick press-formed metal

- Access doors in press-formed metal with heavy duty hinges and screw lock

- Sieve boxes in high-resistance sendzimir galvanized metal, with various components bolted together

- Sieve holder and sieves in sendzimir galvanized metal with wooden components complete with natural rubber beads

- No. 3 sub-product chutes

- Combined movement system: eccentric rotation with damped suspension

- Product feed hopper with counterweight distributor

- Dust winnowing fan complete with: servomotors for air flow regulation dampers, product flow decelerators, sub-product expulsion auger, aspiration inlet

- Automatic stop system fault

- On-board power supply panel, optional box movement inverter and fan speed regulation inverter

Optional

- Variable sieve speed

- Variable fan speed

Specifications

Pre-cleaning capacity from 100 to 200 t/h, cleaning capacity from 70 to 140 t/h (calculated with wheat, specific weight 0.78 t/m3 - RH 14% Impurities 2%).