PRA Rotary cleaner with aspiration

Removes fine impurities in infeed and separates clean product from broken product and waste through the rotary drum.

It is indispensable for cleaning grain destined for long-term storage (prevents overheating due to husk, flours or broken product); at the end of the treatment cycle, product quality and appearance will have improved.

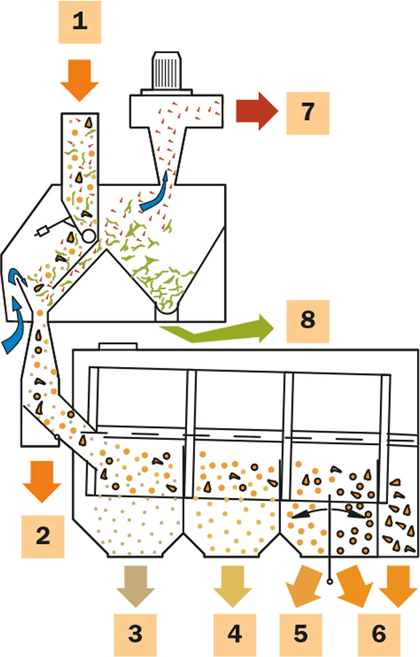

Operating principle

The product enters by way of gravity into a motorised roller distributor and is evenly distributed across the entire width.

The product is then curtain-dropped and struck by a cross-flow of air, which extracts the lightest impurities (decanted by a cyclone or filter).

The heavier impurities are deposited in the decanting hopper, equipped with a waste expulsion auger.

The clean product is fed into a cylindrical rotary drum covered with interchangeable screens. The first screen removes fine impurities (sand, broken grain, etc.),

the subsequent screens allow the clean product to pass through the perforations, and larger impurities at the end of the drum.

The choice of screen depends on the product and type of waste being separated.

Key

1. Uncleaned product inlet

2. Product outlet (bypass)

3. Fine impurities outlet

4. Clean product outlet

5. Clean product outlet

6. Large impurities outlet

7. Dust outlet

8. Fine impurities outlet

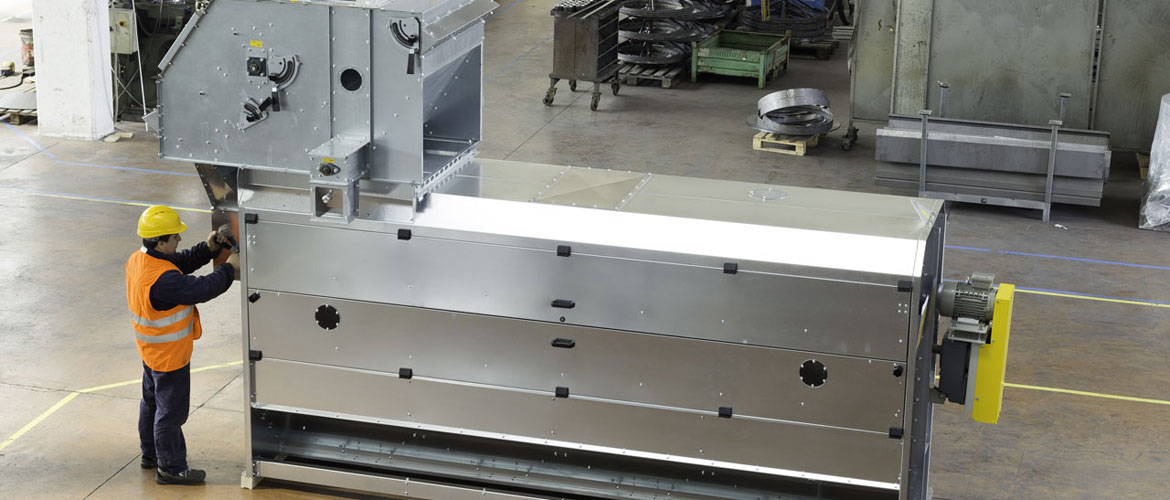

Construction

- Aspiration casing in press-formed galvanized metal

- Product feed hopper

- Aspiration inlet with vertical or horizontal positioning

- Air flow regulation dampers

- Hopper connected to rotary drum

- Drum casing and uprights in press-formed galvanized sheet metal

- Mobile side doors fitted with handle and lock

- Screens in carbon steel

- Manual drum inclination

- Nylon screen cleaning brushes

- Fixed rotation speed

- Conveyor with manual regulation of discharge of large impurities

Optional

- "Variable" drum rotation speed

- Wooden screen cleaning rollers

- Motorised drum inclination

- Wear-resistant polyethylene sheet

- Motorised conveyor

- Control panel

Specifications

Available in various sizes and models with cleaning capacities from 20 to 290 t/h (calculated with wheat, specific weight 0.78 t/m3 - RH 14% Impurities 2%).