CHILLER

The grain chiller is a cooling system that "treats" the temperature and relative humidity of the external air.

Specifications

DESCRIPTION

Dehumidified air is inserted into the silo at a lower temperature according to preset parameters, regulated by the need for optimal storage.

System regulation is entirely automatic. A computer (PLC and touch screen) receives data relative to the temperature and humidity of the external air and product.

It then elaborates the cooling programme to produce large masses of air with characteristics that allow the ensilaged grain to quickly reach the desired temperature.

Construction

Towable, trailer-mounted steel and aluminium load-bearing structure. The front part is equipped with four electric fans that cool the condensing coil, while the intake filters are located in the back part.

CARATTERISTICHE GENERALI

These chillers are the most technologically advanced in the grain cooling machinery sector.

Their operating logic consists in gradual and progressive grain cooling.

Not using air with a temperature that's too low and manually set, but air which, based on the real product temperature,

becomes progressively cooler as the temperature of the mass being cooled slowly drops. All this, completely automatically.

The SIEMENS computer that manages the system continuously monitors the humidity and temperature of the external air, calculating the

necessary temperature, humidity and flow of the cooled and dehumidified air inserted into the silos.

FREE COOLING FUNCTION

The computer automatically decides whether cooling is possible even if the compressor is off, with clear advantages from the point of view of power consumption.

It essentially compares the temperature and humidity of the external air with the product temperature, and turns the compressor either on or off depending on the situation.

ENERGY SAVING FUNCTION

Automatically enables the "ECONOMICAL" cooling function, after evaluating the external conditions in relation to the product being cooled. The system continuously compares the external temperature with that of the product, evaluating when the machine can run on low power consumption or be placed into standby, of course only once the mass product has reached an acceptable condition.

MANUAL OPERATION OF TREATMENT FAN

Allows the machine to be used as a normal fan, with certain on/off limitations:

- Minimum difference in air/product temperature

- Minimum external temperature

- Maximum external temperature

- Maximum external air humidity

DEFROSTING FUNCTION

If ice forms on the evaporator coil, the computer can automatically select a cycle inversion, whereby warm gas is injected into the evaporator to instigate rapid thawing.

HISTORIC DATA FUNCTION

Allows the following data relative to a 24-hour period to be stored for up to 20 days:

- External air temperature

- External air humidity

- Temperature of air inserted into silos

- Product temperature

- Evaporation temperature

- Compressor high pressure

- Compressor low pressure

- Number of defrosting cycles performed

REMOTE ASSISTANCE FUNCTION (OPTIONAL)

By way of a GSM modem for data transmission inserted in the control panel, it is possible to monitor cooling functions, release any operating blocks, reset operating parameters.

MAIN COMPONENTS OF INDIVIDUAL UNITS

- Load-bearing frame made of galvanized steel profiles, casing in epoxy resin coated sheet metal, aluminium profiles

- Liquid separator fitted with safety valve

- Inspectable filter with replaceable cartridge filters in cooling circuit

- Optical indicator of liquid flow

- Manual shut-off valve for main components of circuit

- BITZER compressor

- SIEMENS computer

- SIEMENS TOUCH SCREEN control panel

AIR TREATMENT SECTION

- No. 1/2 centrifugal fans with inverted blades, high pressure and single intake, assembled in a cage frame.

- No. 1/2 B3 type 15 kW electric motors, each 2-pole, directly coupled to the fan axis

- Evaporation/Post-Heating coil made of copper tubes with aluminium finning

- Coolant distributor

- Thermostatic injection valve

- Filtering section, classification EN 779 class G4 Am 95%, limitations of use 80°C RH 90% made of regenerable corrugated synthetic fibre filtering cells in a steel frame in electric welded galvanized steel wire mesh; plastic micro-mesh with electrostatic induction effect

- Condensate collection pan in AISI 304 stainless steel

- Air flow control system by way of an electronically controlled damper driven by a servomotor

MOTOR-DRIVEN CONDENSING SECTION

- Blitzer motor-driven compressor, complete with: intake shut-off valve, integrated differential pressure check valve for electric motor with PTC sensor for temperature control, module to check: missing phase, phase sequence, motor thermistor, compressed gas temperature and compressor start delay, terminal block with IP54 protection

- Unladen and step start devices

- Condensing coil made of copper tubes with aluminium finning

- No. 2/4 fans diam. 630, with external 4-pole rotary motors, complete with nozzles and protective grilles

- Anti-vibration connection to coolant compression circuit in AISI 304 stainless steel

- Gas absorption heat pump defrosting systems

TREATABLE PRODUCTS

The Cooling storage system may be used with the following products:

- Wheat

- Oat

- Barley

- Corn

- Soya

- Sunflower

- Rape

- Rice

- any type of grain

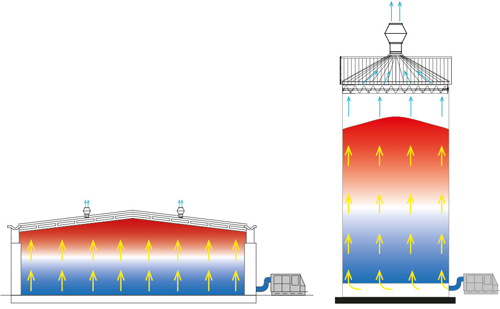

THE PROCESS

Grain cooling through cooled and dehumidified air blowing, allows the rapid lowering of temperatures, thus preventing the spread of mould, toxins, mycotoxins, aflatoxins, bacterial flora, insects, significantly slowing the metabolism of the grain itself. Given that grains are a living product, they breathe, produce carbon dioxide, consume water, oxygen, develop heat, and therefore lose weight. Grain stored at a temperature of +10°C / +12°C produces a quantity of heat, carbon dioxide, water loss, 4 times less than grain stored at +20°C, 15 times less than grain stored at +30°C, 50 times less than grain stored at +40°C. The importance of quickly lowering grain temperature to less than +18°C / +20°C is therefore clear, also in order to slow its metabolism and therefore significantly reduce weight loss.

BENEFITS

Studies on production have demonstrated that a product cooled quickly, as opposed to a product left to suffer at high temperature, has at least 1% less weight loss with respect to the mass. All this translates into more kg of grain in the silo at the time of sale. The resulting economic benefits are clear. No less important is the consideration that properly cooled grain does not require chemical treatments, mechanical movement and inhibits the spread of any toxins that may already be present at the time of harvesting. Cold temperatures cannot improve the quality produced by the soil, but can certainly help to maintain it. In terms of cost, it is worth noting that given grain is generally a poor conductor of heat, once cooled - even if ensilaged in metal silos - it maintains its temperature for 7/8 months. Finally, cooling is the most natural, economical, practical and logical way of storing grain.

Operating principle

The probes inserted into the product inside the silos or sheds send the temperature of the product and the humidity of the external air to the chiller computer. They also send the temperature of the return gas, the humidity and temperature of the cooled air, of the air inserted into the silos, sheds and aspiration and compression pressure values.

This data is all sent to the computer in real time. It is stored and processed in order to determine the system operating parameters in the smallest of detail. The monitoring system is able to evaluate the most appropriate conditions at every instant in order to satisfy specific cooling needs. This cooling system optimises power consumption in accordance with the initial temperature of the stored product, the cooled temperature and the external climatic conditions.