BOX AUGER CONVEYOR

The tubular auger conveyor is used to convey grain - seed - flour products or sub-products along short distances.

Specifications

DESCRIPTION: folded base

The tubular auger conveyor is used to convey grain - seed - flour products or sub-products along short distances, for a maximum of 25-30 m for the folded base version.

The folded base auger is used for bulk loading in small warehouses or for short connections between machines.

Construction

- Steel box with U-section and round or folded base

- Square pitch spiral

- Flanged head-tail supports

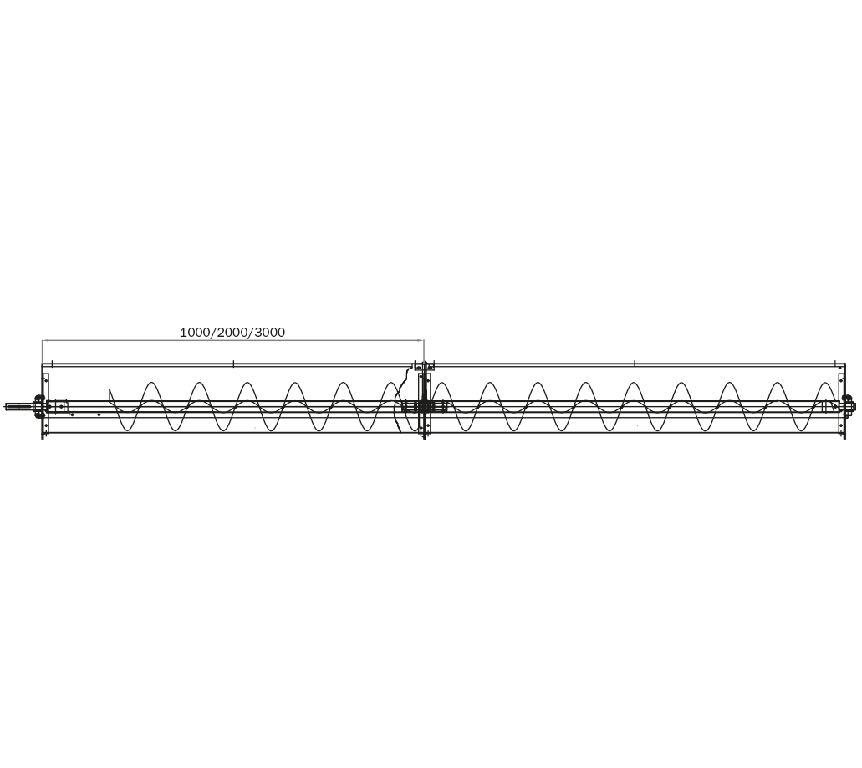

- Intermediate supports every 3m

- Closing cover

- Motorisation: gear motor

- Anti-clogging membrane sensor (or flap)

OPTIONAL

- Pulley drive motor

- Chain drive motor

- Variable-speed motor

- Inverter

- Rotation counter

- Feed hopper

- Discharge hopper

- Intermediate dampers (manual - pneumatic - motorised)

- RAL coating on request

- Hot-dip galvanizing

- 304 stainless steel

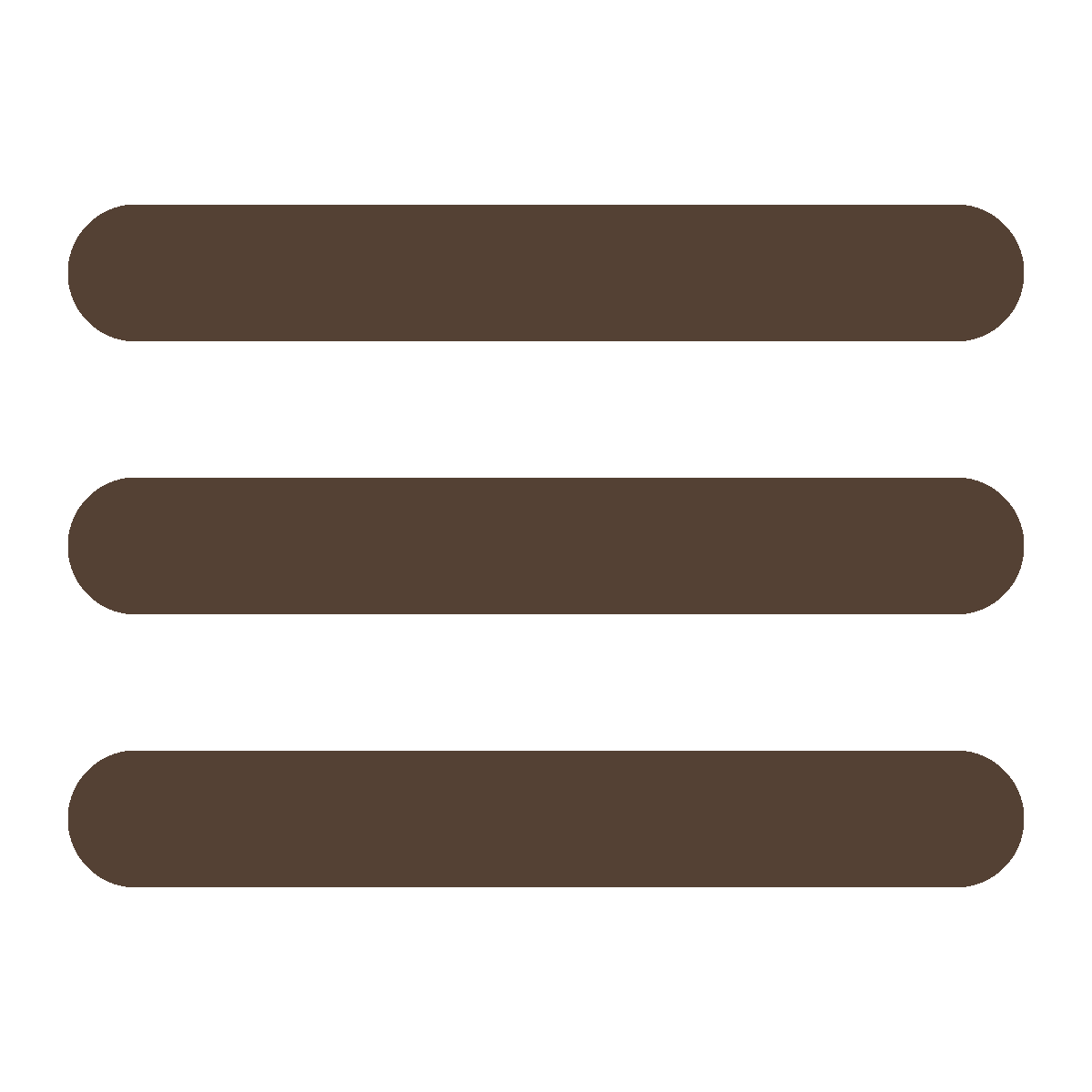

DESCRIPTION: round base

The tubular auger conveyor is used to convey grain - seed - flour products or sub-products along short distances, for a maximum of 15-20 m for the round base version.

The round base auger is used to load processed material into silos or for short connections between machines.

Construction

- Steel box with U-section and round or folded base, sendzimir galvanized

- Square pitch spiral

- Flanged head-tail supports

- Intermediate supports every 3m

- Closing cover

- Motorisation: gear motor

- Anti-clogging membrane sensor (or flap)

OPTIONAL

- Pulley drive motor

- Chain drive motor

- Variable-speed motor

- Inverter

- Rotation counter

- Feed hopper

- Discharge hopper

- Intermediate dampers (manual - pneumatic - motorised)

- RAL coating on request

- Hot-dip galvanizing

- 304 stainless steel

Operating principle: folded base

The product enters by way of gravity into a hopper and falls into an auger, driven by a rotary motion, which advances the product.

The loading capacity depends on the speed and diameter of the auger.

Operating principle: round base

The product enters by way of gravity into a hopper and falls into an auger, driven by a rotary motion, which advances the product.

The loading capacity depends on the speed and diameter of the auger.