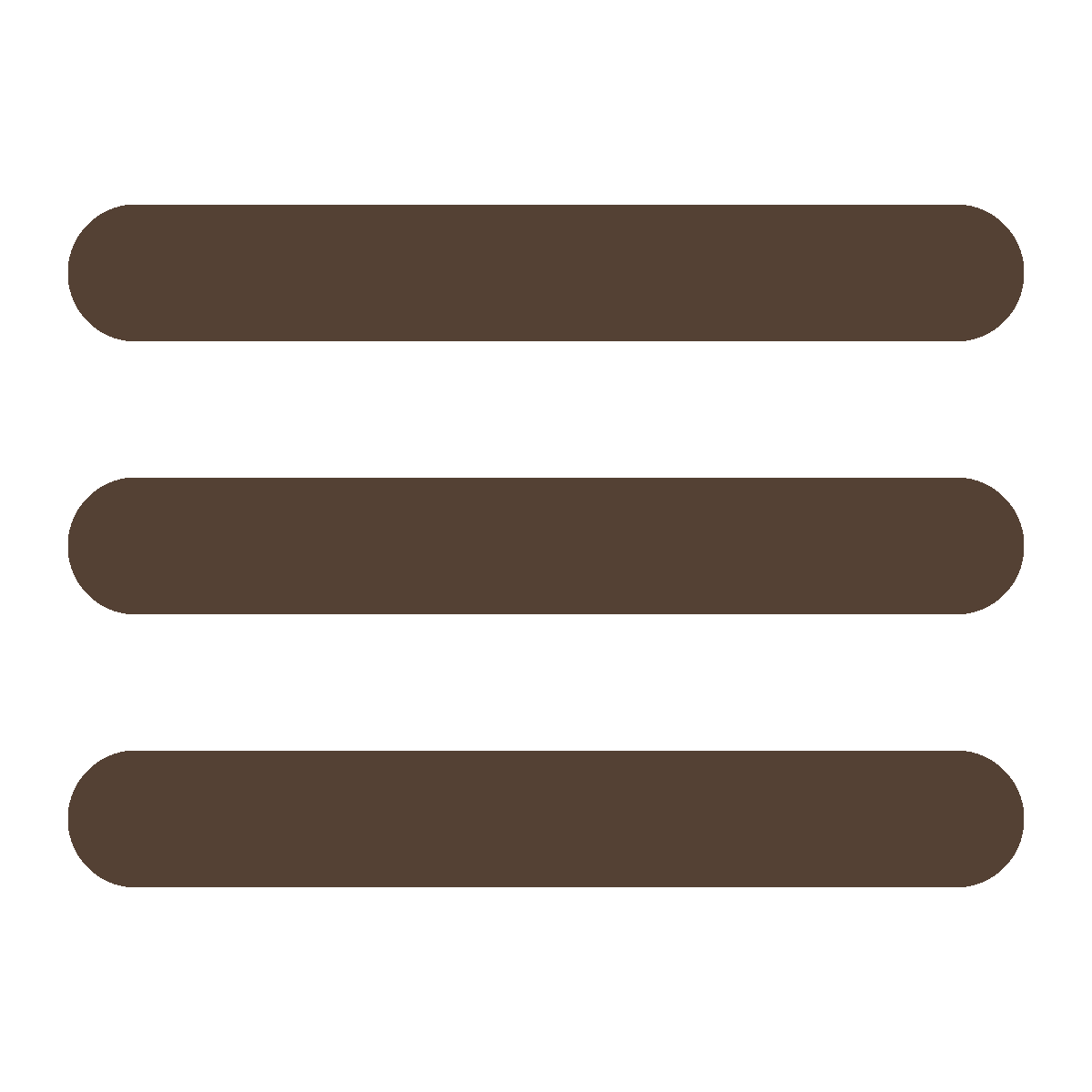

Rotary drum sieve

Treats different product categories, from grain to fertilisers to inert materials.

It has the following functions:

• lump breaking (grain - fertilisers)

• wheat brushing

• draining products of any liquids.

Operating principle

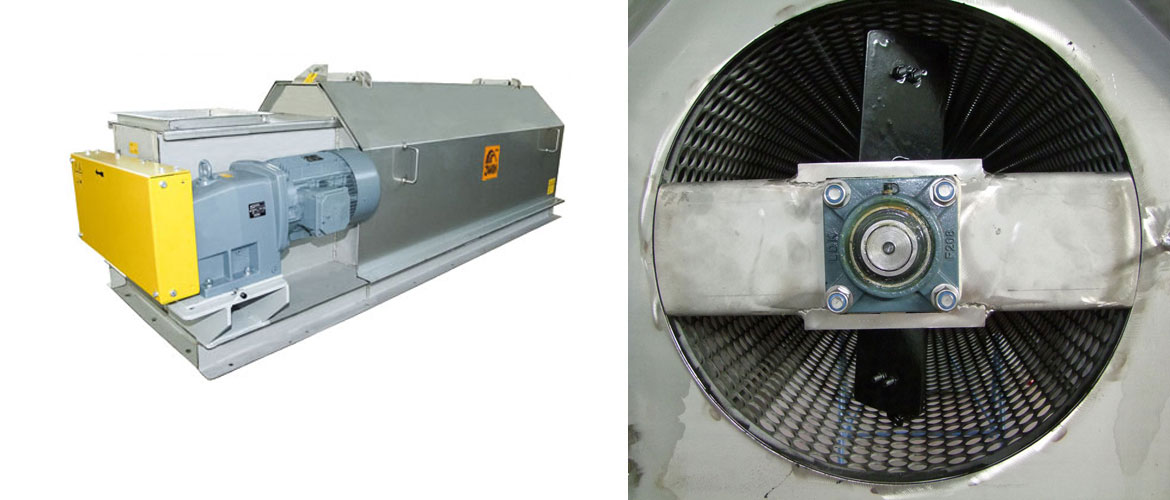

The product enters a hopper with a dosing auger and is pushed inside a fixed drum covered with an interchangeable screen.

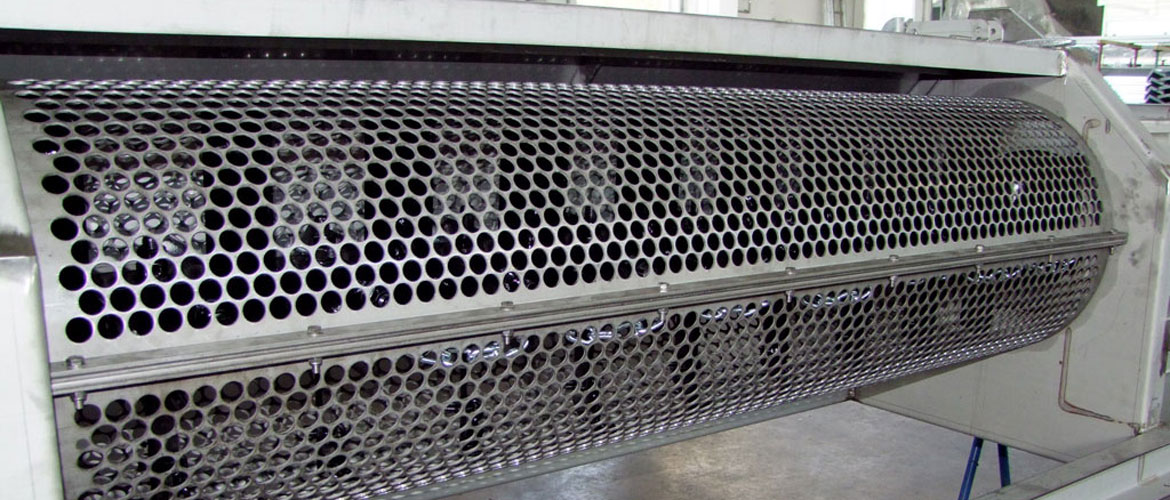

The rotor moves the blades (variable depending on product) to a variable inclination (spiral effect), which advances the product towards the outlet.

A second version can be built featuring awners with variable inclination assembled on the rotor, which perform a centrifugal action to expel fine impurities

outside the screen, with the clean product discharged at the end of the drum.

Possible solutions are:

A: Clean product sent to the end of the drum and the sub-product passes through the perforations.

B: Clean product passes through the perforations and the sub-product is discharged at the end of the drum.

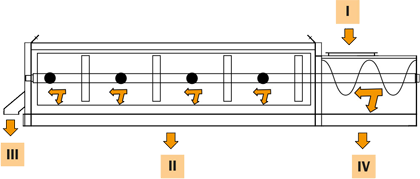

Key

I. Product inlet

II. Fine impurities / liquid outlet

III. Product outlet

IV. Bypass (optional)

Construction

- Drum casing and uprights in press-formed carbon steel

- Mobile front door secured with bolts

- Rotor complete with spiral, blades and supports

- Screens in carbon steel

Optional

- Inlet bypass

- Stainless steel construction

- Stainless steel screen

Specifications

Available in various sizes and models with capacities from 40 to 90 t/h (calculated with specific product weight 0.9 t/m3 R.H. 1%, impurities 2%).