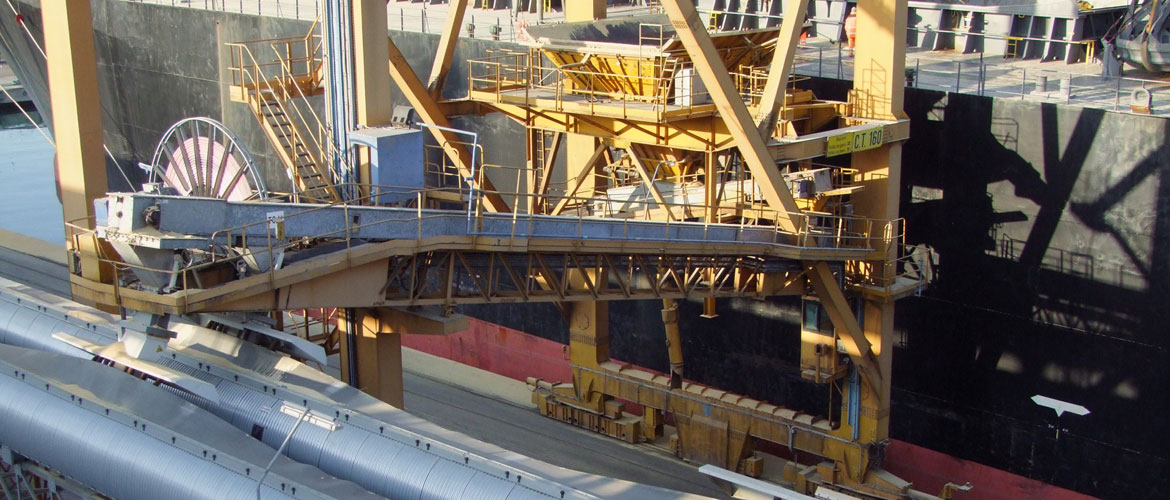

CHAIN CONVEYOR - INDUSTRIAL

The chain conveyor is used to convey granular products.

Specifications

Available in various sizes and models with capacities from 120 to 950 t.

DESCRIPTION

The chain conveyor is used to convey granular products.

Used to convey ensilage products in a horizontal direction, in processing towers, processing machines and for quick loading.

Suitable for all fluid products with varying capacities; it is reliable and hermetic.

Construction

- Head and tail in reinforced “sendzimir” galvanized metal

- Rectangular metal box, bolted, “sendzimir” galvanized

- Scraper chain in special steel

- Motorisation: direct drive gear motor

- Chain guide in polyethylene

- Anti-clogging membrane sensor

- Inspection window on head

OPTIONAL

- Chain drive motor

- Variable-speed motor

- Rotation counter

- Feed hopper

- Discharge hopper

- Explosion-proof panels

- Forged chain

- ”Hardox” wear-resistant plate across box floor width

- RAL coating on request

- Hot-dip galvanizing

- AISI 304/316 stainless steel

Operating principle

The product enters by way of gravity, a linear chain motion moves the product to the opposite side and releases it in a discharge hopper (optional).

The capacity depends on the chain speed.